Stage separation system design was my paper presentation that i had done at college. This paper was looked into by Prof. A.K Saha , Dean NEHRU GROUP OF INSTITUTIONS , Kerala and Coimbatore ,one of the former colleagues of Dr. APJ Abdul kalam at ISRO.

Introduction

The “Space age” will also be the “Rocket age” since rockets will be the main means of traveling in space. Of the various kinds of rocket engines, the traditional rocket engine , in which a fuel and an oxidizer are mixed and the hot gases produced are ejected in the opposite direction of travel, will be the space vehicle or “work-horse” of life in space, like motor car engines on earth.

Space operations are extremely expensive and space engineering is still a small and specialized field.

Launch vehicle design & reason for staging:-

The problem: Many people think it’s difficult to get to orbit because it is so high but 200 kilometers isn’t far at all. And you can get to 100 km altitude by accelerating to only mach 4.5 vertically, but you just fall back. You won’t stay in orbit unless you circle the earth at about 8 kilometers /second

The main problem of getting to orbit is to accelerate to mach 26 or a speed of 8 km /sec. airlines fly at less than mach 1, even Concorde flies at only just over mach 2. So we have to go a lot faster to get into orbit. To accelerate, of course, we require fuel or propellants, as rocket engineers say, because liquid propellant rocket engines use fuel and oxidizer.

A lot of propellant is needed to get to orbit. But to get to orbit a rocket needs to be about 90% of propellant so all the rest of the rocket including pay load weigh only about 10% .Therefore space vehicles are very very heavy. It also needs to be made very strong so that it can survive acceleration, vibration & aerodynamic stresses.So, to simplify the problem, space vehicle are multi staged. That is there are several components called stages all stacked on top of one another and fired in succession. Each stage has a rocket with its own propellant. As a result, in multi stage launch vehicles only a small part of the rocket actually reaches mach 26 & goes to orbit & so we need not make the whole structure light & strong so as to enable the whole structure itself to go to orbit. The first and second stages can be heavier.

A typical launch vehicle may have several separation events such as

a) Stage separation

b) Strap on separation

c) Heat shield separation

d) Ullage rocket separation

e) Space craft separation

Separation of stages during atmospheric flight is of utmost concern since aerodynamics plays an important role. As the separation process is always mission critical, hence the level of analysis required to make assessment on the adequacy of separation system is very important. This requires accurate modeling of various forces and moments acting on the separating bodies. They are forces and moments due to

a) Gravity

b) Retro/ Ullage rockets

c) Tail off thrust

d) Jet damping

e) Release & Jettisoning mechanisms etc

Information on the critical design parameters can be obtained from the dynamic study of separation process.

Separation clearances, relative separation velocity requirements, short term & long term collision avoidances, tip off errors, Sensitivity analysis is types of information needed from these design support studies failure modes and its effects studies should be performed where ever possible. If complex forces and moments occur, then 6 degree of freedom simulation of the separation processes is recommended.

Each body’s motion should be simulated will all the forces & moments acting on it with or without elastic effects included. These forces and moments are modeled and the governing equations of motion are analyzed for occurrences of collision.

Selection of stage separation system

Selection of stages separation system of launch vehicle is an extensive & exhaustive process. It is primarily governed by system requirements. The critical criterions are

v Joint rotation

v Simultaneity

v Reliability

v Confinement of debris

v Low shock levels

v Weight

v Cost

The selected separation system should also meet all the functional requirements viz,

v To achieve collision free separation of spent stages, ie, to establish clearances, between the separating bodies to ensure safe separation.

v To provide the structural rigidity to attach the two bodies, the ability of the mechanism to withstand the flight loads encountered during flight that is structural integrity should be maintained.

v To provide the means to severe the structural connection

v To impart positive separation velocity to the separation bodies.

v To impart minimum tip off rate to ongoing stage.

v Minimum shock transmission to the payload interfaces or the continuing stages

v No damages due to contamination for the continuing stages

v To achieve separation in minimum time so that the “no-control duration” of the flight can be minimum

Separation elements

Generally three basis elements are required for the functioning of separation process.

a) An actuator -to trigger the event usually electric or pyro based

b) Release / Severance system for physical separation

c) Jettisoning systems – to impart sufficient relatives separation velocity

1) ACTUATOR :-

The actuator system as the word indicates actuates the triggering of the separation event. Thus, there is a delay between actuating the trigger and physical separation. Usually actuators are either

a) Electric or

b) Pyro based.

Usually a central command governs all the actuating signals.

2) SEVERANCE/ RELEASE MACHANISMS.

The severance/release systems impart physical separation to bodies; they are primarily 2 types;

a) Mechanical systems &

b) Pyro –technique devices.

The design requirements for these systems are;

v Load carrying capability & compatibility with vehicle structure.

v Minimum electrical power for separation system.

v Minimum system weight & minimum volume.

v Minimum impulse & minimum tip off rates.

v High reliability, maintainability & long storage life.

v Survival of extremely high or low temperatures

v No contamination, debris free & survival of nuclear environment

v Safe handling & easy transportation.

A) mechanical systems

1. Ball & lock systems

Ball & lock system consists of upper & lower stages adopter rings held together by steel . Balls which in turn are held by a retainer ring. The retainer ring is provided with escape holes for balls.

In the locked condition, the holes in the retainer ring are given an angular offset. During release, pyro-thrusters rotate the retainer ring which nullifies the offset. The pyro thrusters are initiated by pressure cartridges an electrical command from the central sequencer of the vehicle. A stopper limits retainer ring rotation.

Helical compression springs positioned between the flanges impart the required differential separation velocity.

The lower stage outer ring is provided with through holes for the balls in the locked condition and the upper stages adapter ring is provided with conical ball seat, the radial component of the spring forces pushes the balls outward & releases the inner ring which ensures a clean separation.

Fig [1] – BALL AND LOCK MECHANISM

Multistage launch vehicles use clamp band joint for separation of upper stages & payload fairing. The necessary preload on clamp is given by tensioning two steel band segments placed over the clamps & connected by two tension bolts & nuts.

In this type of joint the tapered interfaces flanges are held together by a series of aluminum clamps made of m250 steel circumferentially positioned. These clamps are preloaded using two steel band segments through two connecting bolts & nuts under tension pyro-cutters severe the connecting bolts when separation of the joint is required.

For structural integrity, of these joints band tension of 10 to 100 KN is to be applied depending on the expected loads at the joints.

These are low shock contamination free devices & are capable of taking very high structural loads. They are simple & provide clean & low shock separation.

PSLV uses band joint for the separation of second stages, payload fairings & space craft separation GSLV uses band joint for the separation of payload fairings & spacecraft.

3. COLLET MECHANISM.

The collect mechanism is as shown in consists of a collect housing / cylinder with a piston holding the finger spread out in locked position. The mechanism can carry tensile loads when in locked position. When gas pressure is introduced in to the cylinder bore it acts on piston causing it to move forward & allowing the collect fingers to collapse due to their strain energy. This action permits separation of the vehicle from the spent stages. The device is capable of resisting high tensile loads to present gap of the interface during ground & flight.

It can withstand the flight dynamic loads as specified this systems provides firm

Structural connection for the load transfer across the joint. Response time of the is about 20 ms tip off error due to separation carry small. It withstand a maximum temperature Gradient from 80 K 353 K this system has to be protected from excessive aerodynamic Heating using cowlings & it has to be made waterproof for reliable operation.

This system provides a debris free clean separation. The second and third stage

separation system of GSLV consists of 8 projects activated collect release mechanism

located at the truss of the cryo stage lower adapter ensures collision free separation.

Four retro rockets are used to impart the required separation velocity of 4 m/s.

B) PYRO SEPARATION DEVICES

These systems use pyro active element for imparting physical separation, two types are commonly employed they are,

1. Explosive Bolt:

In the explosive bolt, the pyro charge is electrically initiated to severe the bolt at notches provided at separation planes.

2. Frangible nut: In frangible nut pyro activation causes the nut to open out and to release the studs engaged in nut threads.

Two main pyro release mechanisms employed in multi stage launch vehicles are:

1) FLEXIBLE LINEAR SHAPED CHARGE

FLSC is used in launch vehicles for stages separation especially for lower stages. The basis components of FLSC separation system is the shaped charge which consists of a V position over the structural member to be cut. Shaped charges are the only form of pyrotechnics used not only to control the direction of explosive but also to concentrate it.

The severance by FLSC is by jetting due to V shaped charge; the total cut is the net effect of the two phenomenons.

a) Penetration by jet

b) Shock severance

Generally; penetration is about 50% of the total cut with shock induced fracture accounting for the balance. The separation is achieved by severing the machined end ring of; the inter stage or by severing the skin of the inter stage for efficient and clean separation.

FLSC is selected for PSLV & GSLV primarily because of it is large diameter of inter stages.

The selection of FLSC is primarily governed by the system requirement like

a) Joint rotation

b) Simultaneity

c) Reliability

d) Weight

e) Costs etc.

The FLSC system is simple & reliable. But it generates high levels of shock & contamination shock level depends on thickness & type of material being cut.

- ZIP AND SUPERZIP

The two basic drawbacks of unconfined detonating Cords are the shock and contamination. To avoid these new design concept of encapsulating the detonating cord initially in a metal tube and subsequently for flexibility in this confinement in a polymer tube. This concept is called Zip or Super-Zip. Due to the limitations at high temperatures about 200 degrees Fahrenheit, a flat thin the stain less tube. With an inner polymer container this technique is called Super-Zip. This is used in longitudinal and circumferential joints. Shock is reduced to 1/3rd level. High reliability is achieved through redundancy and contamination through due to gas is prevented.

JETTISONING DEVICES

These systems have been used to provide the required relative separation velocity to the separating bodies. Energy required for jettisoning the systems are provide by employing anyone of the following type of thrusters,

v Spring thrusters

v Pneumatic thrusters

v Rocket thrusters

Choice if the type, number and size of the thrusters depend on mass and velocity with which the spent stages are to be jettisoned.

The Ejection/Jettisoning system design requirements are;

v Imparting a well predictable differential velocity to the separating bodies

v Minimum tip off rates and minimum acceleration jump at separation

v Long storage life

v Survival of extreme high, low temperature and nuclear radiation

v No contamination, maintainability and high reliability

v Minimum weight and minimum volume

v Compatibility with vehicle structure.

v No debris and safety

Some of the Jettisoning systems usually employed in launch vehicles are described below:

1. SPRING THRUSTERS

In spring thrusters, springs are packed and compressed to the required energy level. Disc springs depending or coil springs are employed depending on the jettisoning requirements; high energies are met with disc springs. The advantage of spring thrusters is that spring energy characteristics can be evalued prior to the assembly of the system and once assembled jettisoning spring force is always available for the function. Thus, separate command is not needed for the actuation and is highly reliable. To draw back with the spring thrusters is that they are heavier compared to the other types of jettisoning system. For smaller mass with lower energy requirements spring thrusters is an ideal choice whereas for large size boosters with higher jettisoning energy requirements their use is not recommended.

2. ROCKET THRUSTERS

Rocket thrusters are used for jettisoning higher diameter massive boosters where the associated energy requirements are higher. The advantage of the rocket thrusters is that it can store much higher energy for a given weight of thrusters.

3. PNEUMATIC THRUSTERS

In this type, the working medium is pressurized nitrogen gas. These thrusters are light in weight as the working medium is gas. The energy stored depends on the initial pressure and stroke length and there for by changing the pressure stored energy also can be varied. The pressure holding characteristics of the rolling diaphragm and joints is the limiting factor for the stored energy. Pneumatic thrusters do not require separate command for actuation as the jettisoning force is always available. In all these types the separation relies on the addition of an auxiliary system for jettisoning the spent stage. The burn out of spent stage, separation and ignition of the continuing stage are made sequentially with out coasting in between them. The ongoing stages engine ignites only after two stages have been separated. Therefore these types are called cold separation.

In these options the hardware design is simple, relatively steady operation process, less disturbances no exhaust ports are required and heat insulation is required. However there can be long no; control duration and reliability is very high.

VENTED INTERSTAGE SEPARATION (HOT SEPARATION)

In the hot or vented interstage separation the adjacent stages are separated by the impingement of the hot exhaust gas jet from the engine of the ongoing stage. The engine of the ongoing stage ignites when the two stages are still connected together. This type of separation is called hot separation or fire in the hole staging. The engine of the continuing stages is ignited at a time much before the occurrences of burned out stage separation. Thus, eliminates the need for jettisoning devices to provide the separation impulse. When the thrust build up of the upper stage reaches some level, the release mechanism is initiated and physical separate take places. In this case, provision for venting the exhaust gases from the continuing stage is made in the interstage attached to the spent stage. This option provides relatively less no control duration, high separation force and high reliability. Sturdy heat insulation layer should be added on the top of the lower stage tank to prevent damage due to the high pressure and hot stream of engine exhaust from the upper stage. However the design of the structure has to consider the high temperature environment.

Fig [3] – VENTED INTERSTAGE SYSTEM OF GSLV

The hot gas separation system is a passives system. It eliminates the uses of retro and Ullage rocket system, thus enhances the reliability and hence makes it robust as hot gas separation system allows the ignition of the ignition of the second stage prior to separation there is a considerable reduction of the none control duration.

Stage separation of launch vehicles

In multistage launch vehicles the spent stages separation process is broadly classified in to two classes.

1. Separation occurring during atmosphere ( booster/lower stage separation)

2. Separation occurring out of atmosphere (vacuum /upper stages separation)

Dynamics of atmospheric separation is very complex due to the presence of aerodynamic forces and moments acting on the separating bodies. On the other hand upper stage separation is comparatively simpler due to benign environment.

Lower stages (separation system)

Lower stage or strapon separation as the name indicates are the rocket motors strapped on to the core motor to boost the payload capability of the vehicle by on board command once their intended functions are over. The direction of separation can be fixed to avoid collision hazards to the core vehicle, unlike the separation of other stages, which are usually in the axial direction, separation and jettisoning the strapons is one of the most challenging tasks due to the complexity of separation dynamics analysis involved particularly when the strapons are to be separated at high dynamic pressure environment and when more number of strapons are involved in the separation process.

The strapon separation system has to perform following.

1) The separation system joints must provides a rigid attachment with the core vehicle to effectively transfer the strapon thrust and control forces to the core vehicle and must withstand the aerodynamic loads that are expected in fight.

2) The strapons must separate on command as pr the designed flight sequence and the separated strapons must be jettisoned with sufficient energy; to ensure no collision with the core vehicle.

LARGE BOOSTER STAGE SEPARATION:

During the last two decades, the demand for heavier spacecraft mass has been made to satisfy the increased user requirements. Accordingly multistage launch vehicles are configured with large sold strapon boosters. The separated body should not rebound and collide with the core vehicle by the action of impingement of jettisoning jet plume. The separation disturbances shall be within the control capability of the core vehicle. As the spent stage inert mass is very heavy about 30 tons, the selected system should provide strong thrust and be able to withstand the tail off thrust of spent strapon stage. Considering all these, side rocket system has been chosen as jettisoning system.

The booster stages are separated from the vehicle during it’s tail off thrust and the thrusting phase ( control is on ) of the core vehicle by the severing strapon joints (ball and socket)at the top and the three strapon links at the aft end of the pyro assisted mechanism. The jettisoning rockets are mounted in the nose cone and the base shroud provides the necessary separation velocity for the booster stage to achieve separation .This is achieved by employing 5 number of side rockets per strapon (2 numbers at the forward end 3 numbers at the aft end so that the spent body can be taken away from the vicinity of the functional stage. The number of sides rockets 2 at the forward end and 3 at the aft end are decided in such a way that the ;spent body will be moving with out any rotation as the spent body C.G. is placed towards the base shroud.

Fig [4] – LARGE BOOSTERS CONFIGURATION

HEAT SHIELD SEPARATION

The primary function of heat shield is to protect the payload and other sensitive system of launch vehicle from the aerodynamic and thermal loads during its ascent phase of flight and to provide the aerodynamic shape and thereby reduces the aerodynamic drag. After meeting the functional requirements the heat shield should be separated from the launch vehicle as early as possible. The system used for separation should impart necessary jettisoning velocity to achieve collision free separation. The heat shield is usually made in two halves and attached through separation system. The velocity required for safe separation depends on the heat shield diameter, mass, flexibility and the state of motion. However as the diameter and length of the heat shield goes up flexibility plays a major role in safe separation. Also for many vehicles the heat shield separation takes place in thrusting phase. All these factors necessitate a larges separation velocity and jettisoning system to impart this velocity as quickly as possible. For these reasons the PSLV and GSLV have adopted a zip cord as jettisoning system for vertical separation. The separation dynamics of heat shield is studies by combining the rigid body as well as flexible motions of the fairings using finite element method.

Fig [5] – HEAT SHIELD SEPARATION

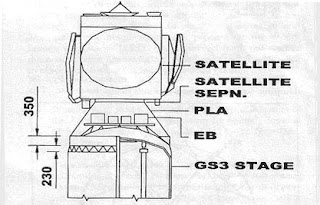

CRYO STAGE I SATELITE SEPARATION

A merman band type separation system with bolt cutters on either side is provided at the space craft payload interface. 12 helical spring thrusters mounted in the payload adapter provides the necessary separation velocity of 1 m/s to the spacecraft. The specifications

Fig [6] – SPACECRAFT SEPARATION:

of spring thrusters used were given in table 1 the separated cryo stage residual gas of the storages tank container provides a large number of thrust generation sources. These thrust sources are quantified and their thrust action points were identified. Using table 1 and residual forces and moments generated separation dynamic analysis are carried out for short term and long term collision hazards. It is then predicted a collision free space craft separation and it will be experienced in the flight.

CONCLUSION:

A brief outline of the design and analysis guidelines followed for the selection and design of stage separation of space launch vehicles are dealt with. The complexities associated with the atmospheric and upper atmospheric operation are also discussed. The separation dynamics problem is modeled around the forces and moments acting on the vehicle, which is of very high magnitude. In such cases, the bodies are treated as rigid and the various forces and moments influencing the body dynamics are modeled using an object oriented approach. The mathematical formulation of the six degrees of freedom simulation packages are developed using the same approach.

The simulation presented during the seminar and submitted with the soft copy of this report is one such package. More sophisticated and high end software tools helps in not only visualizing the flight trajectories and paths of spent stages but also in simulating the exact effects of various design parameters in the flight of the space launch vehicle to an amazing degree of accuracy.

Software tools are developed funded exclusively by government agencies like NASA, ISRO and are used for both design and analysis of the stage separation process in space launch vehicles. It is observed from studies that the results are extremely encouraging. The predicted (both calculated and simulated) results were in close match with the flight-experienced results.

Using these we can make a thorough analysis of all aspects of stage separation systems, right from selection of devices and elements used in separation systems to assessing the adequacy of the same on the basis on critical parameters that were discussed in detail and the overall launch objective which is success of the mission.

v JOURNALS

1. D.Jeyakumar and K.K.Biswas, “Journal of Aerospace Sciences & Technologies” volume 55, No.3, pp 211-222, August 2003

2. Kumpel, P. Barros, C. Burg, F. Villeneuve, “A Conceptual Design for the Space Launch Vehicle”, AIAA (American Institute of Aeronautics and Astronautics) Journal 2002-vol no 5854, ►Downloaded from www.asdl.gatech.edu/publications/pdf/2002/AIAA-2002-5854.pdf

3. R.V.Perumal, B.N.Suresh, D.Narayana Moorthi and G.Madhavan“First developmental flight of Geosynchronous satellite launches Vehicle (GSLV-D1)” Current Science, Vol 81, No.2, 25/07/01

v CONFERENCE PROCEEDINGS

1. Biswas K.K, “Some aspects of Jettisoning dynamics related to launch vehicles”, Proceedings of the International Conference on Space Dynamics and Celestial Mechanics,D.Reidal Publishing company,1986,pp 369-379

2. Andrew Peffer, “Development and Transition of Low-Shock Spacecraft Release Devices for Small Satellites”, Proceedings of the 14th Annual/USU International Conference on Small Satellites, volume # SSC00-XI-5

3. Schindwolf, Swanson, Millard, “Launch of “Smallsats” Using Low-Cost Sounding Rocket Technologies, Methods, and Practices”, Proceedings of the 12th Annual/USU International Conference on Small Satellites, volume # SSC98-III-2

For the past few days, I have been looking for reading material on separation systems but to no avail. This helps quite a bit. Thanks :)

ReplyDeletethanks for the valuable information it added a detailed stuff to my project done in ISRO

ReplyDelete